How do charging and discharging work?

THERMAL ENERGY STORAGE FOR STEAM DECARBONISATION

Charging

Renewable electricity is converted into heat through electrical resistance heaters. Cold tank salt circulates past the heaters, heating up to 600ºC. This energy is then stored in the hot tank, ready for use, whether in hours or days.

Discharging

When it’s time to discharge, the hot salt releases its stored energy by flowing through a steam generator. Here, it transfers heat to water, creating high-temperature steam for heat or cogeneration. The cooled salt returns to the cold tank, ready for the next cycle.

See how Hyme’s solution works

WHAT MAKES OUR SOLUTION DIFFERENT?

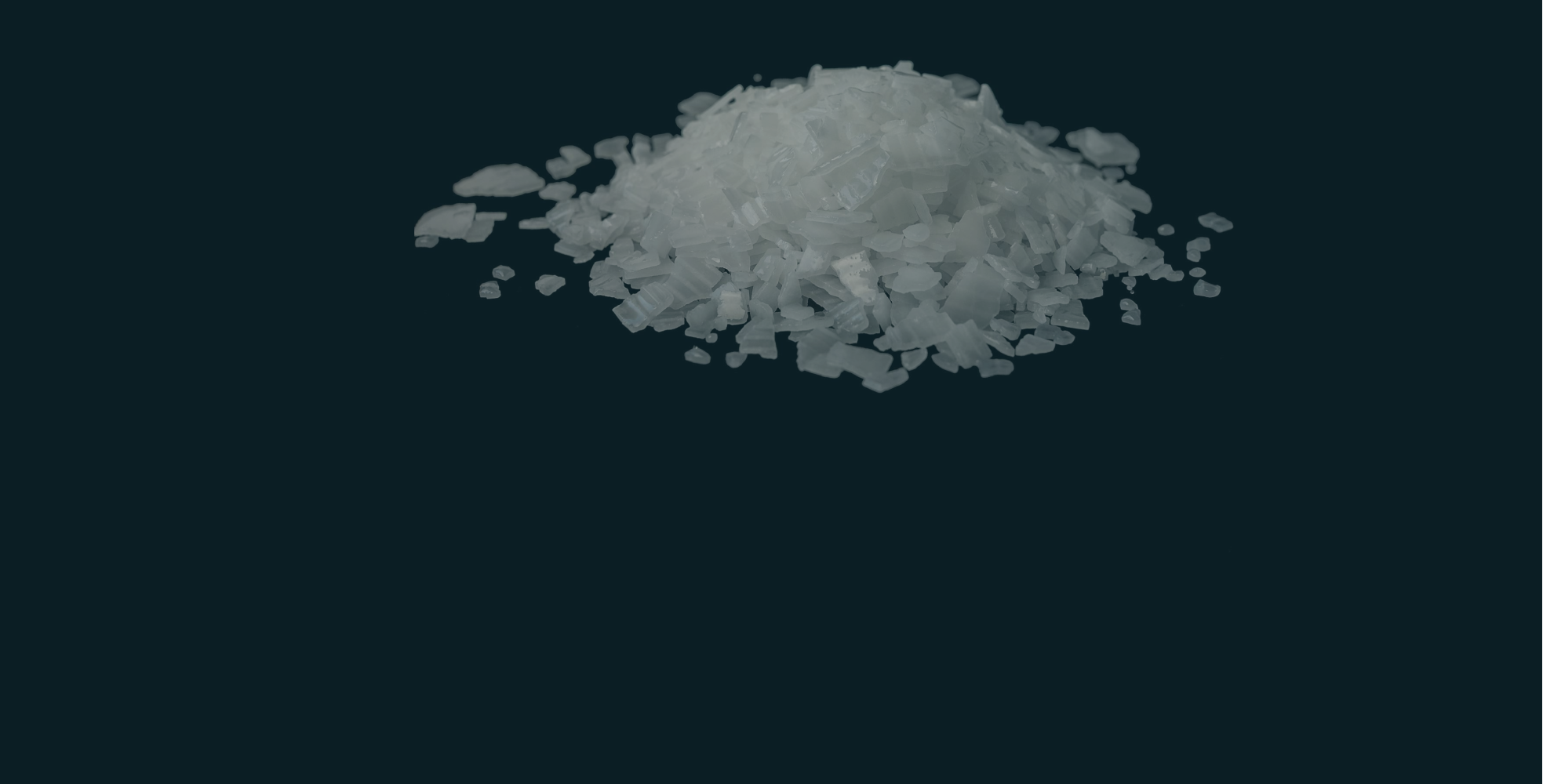

Hydroxide salts: the key for efficiency and affordability

Hyme uses a unique family of hydroxide salts that enable greater efficiency and cost savings compared to other salts in the thermal energy storage market.

Sustainable &

abundant

Derived from seawater, hydroxide salts face no supply constraints.

Compact &

efficient

High energy density allows for a compact system, while high thermal conductivity boosts equipment efficiency.

Low cost

Hydroxides are the most affordable salt storage medium, with high energy density reducing structural material needs.

Safe

Non-toxic, non-flammable, and low-pressure.

SALT TREATMENT

Innovation in action

Our team of world-class chemistry and materials science experts is breaking new ground in high-temperature molten hydroxide storage. Using our own salt treatment methods, we’re scaling these solutions for industrial use. Hyme is also refining salt blends to boost the thermal performance of molten hydroxides in energy storage.

OUR CAPABILITIES

Molten salt labs

At Hyme’s R&D labs, we’re constantly testing materials and components to drive down costs and optimise our designs, pushing the boundaries of what molten salts can deliver.

Prototyping facility

Our prototyping facility in Southern Copenhagen is where we design, build, and operate custom equipment and experiments to deepen our understanding of molten salts in real-world applications.